Modular & Re-deployable Rail for Evolving Mines

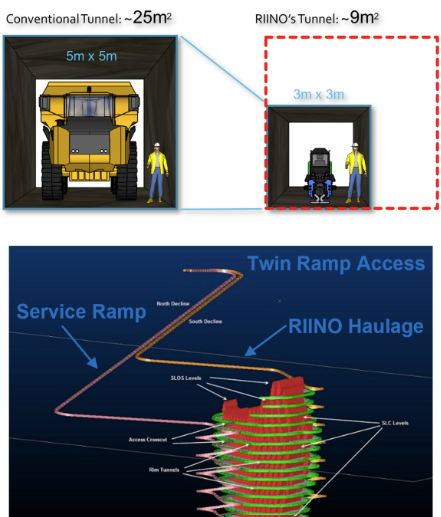

RIINO’s electric rail haulage system is designed to adapt to the realities of modern mining, where operations shift over time and infrastructure must adapt. The modular track design allows the system to be deployed, extended, or relocated as needed, supporting both short-term phases and long-term site development.

For operators managing multiple pits, satellite deposits, or nearby facilities, the system can be configured to:

Connect mine to mill efficiently

Link multiple mine sites within the same region

Extend haulage to satellite or lower-grade deposits without requiring new permanent roads or large fleets

Redeploy track infrastructure as pits advance, close, or shift over time

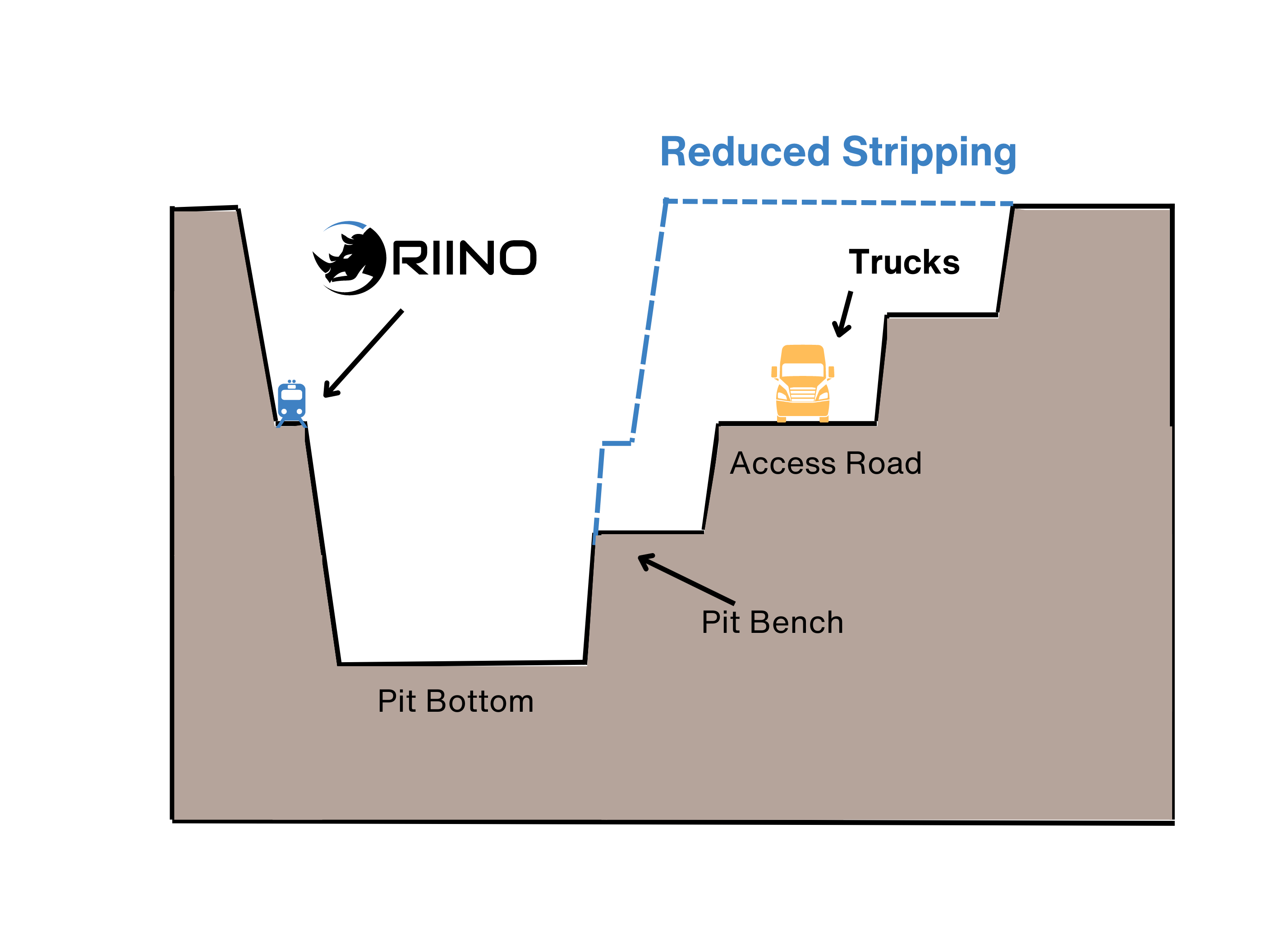

This flexibility reduces the need for repeated construction and minimizes disturbance to the environment. Compared to traditional haul roads and truck fleets, RIINO’s system can help reduce:

Earthworks and surface disruption

Construction timelines and upfront capital investment

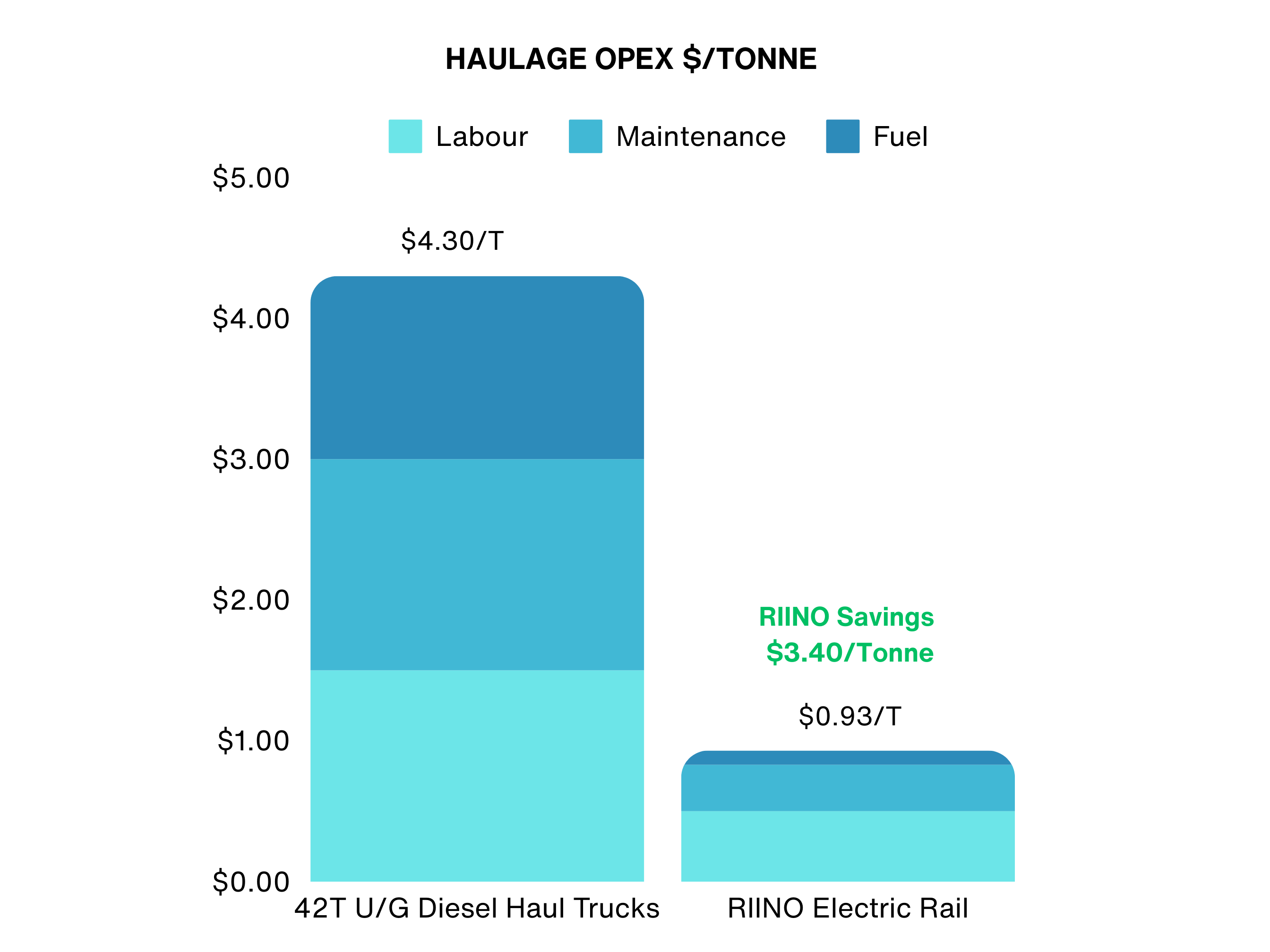

Operational costs associated with diesel haulage and road maintenance

It also opens up access to smaller or previously unfeasible deposits, especially when the system is already in use onsite. RIINO provides a way to scale responsibly, optimize over time, and extend the value of existing infrastructure.